[Application]

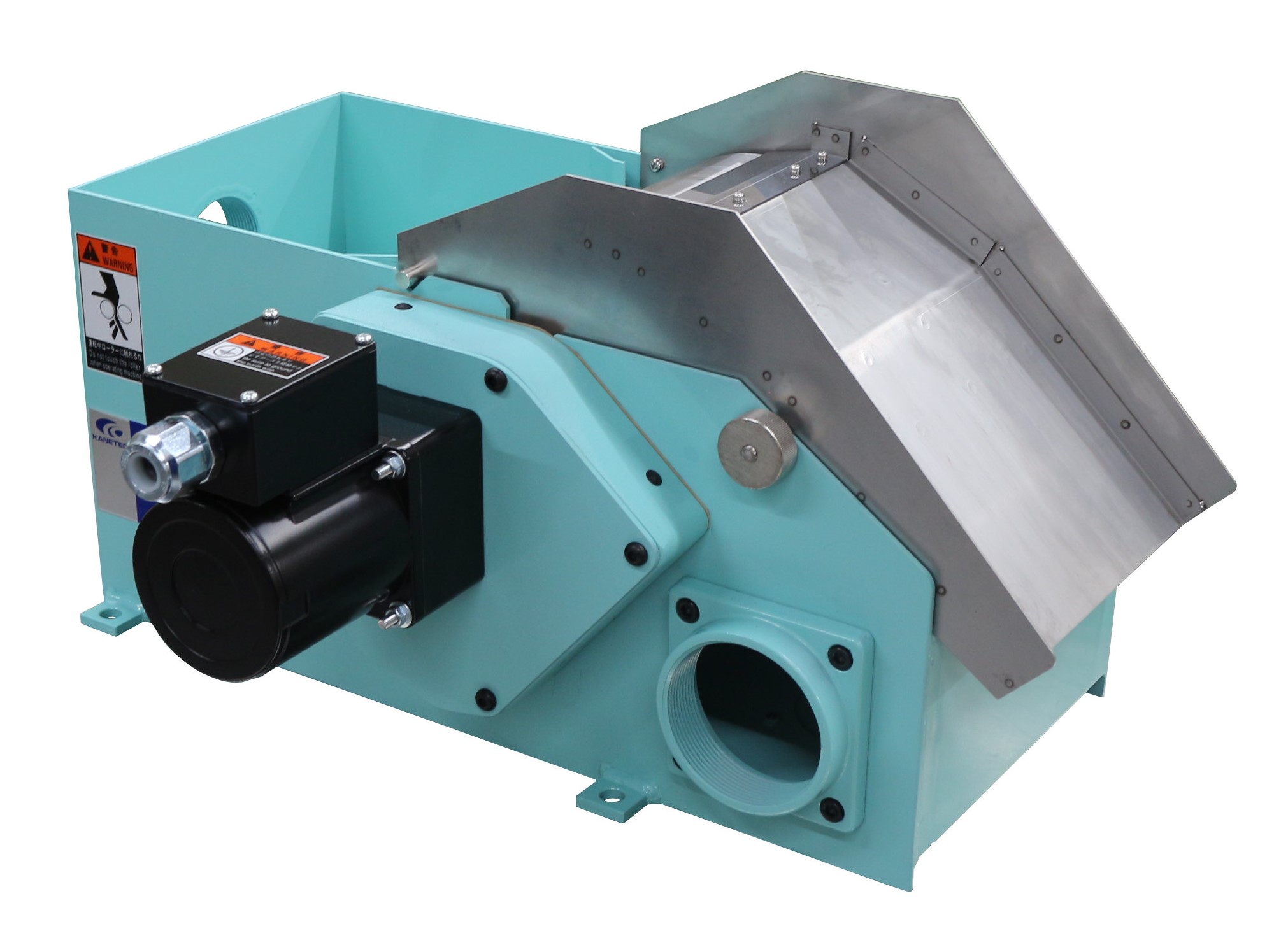

This Chip Magclean is designed to remove/collect chips in coolant that is discharged from cutting operationd by machine tools.

[Features]

- Use of strong magnets with unique magnetic array ensure a high collection rate.

- Newly designed scrapper improves performance to separate and remove cut waste from the magnetic drum.

- Expanded discharge chute helps stable feed out for removing of scrap waste. Higher side wall helps prevent spill over leakage.

- Overall height is reduced by 80mm, increasing opportunity to install in small, limited spaces.

| Model | Processing Capacity | Power Source | Motor | Dimensions |

|---|---|---|---|---|

| CMS-4B | 40L/min | 3-phose 200/220VAC 50/60Hz |

25W | L505×B361×H280 |

| CMS-8B | 80L/min | L505×B411×H280 | ||

| CMS-12B | 120L/min | L515×B561×H280 |

■Applications of Magclean

| Machine tools and Equipment |

Iron Powder(Sludge) and Chips |

Magclean | Chip Magclean |

Paper Filter after Treatment by Magclean |

Magclean after Separeation and Collection by Chip Conveyor |

(Ref.) Chip Conveyor |

| Precision grindfing machine Honing machine |

Sludge Fine iron powder |

△ | ☓ | △*1 | - | ☓ |

| Cylindrical grinding machine Centerless grinding machine Surface grinding machine Rotary grinding machine |

Flocculent fine iron powder |

〇*3 | △ | 〇*1 *3 |

- | ☓ |

| Fine iron powder | 〇 | △ | 〇*1 | - | ☓ | |

| Machining center Milling machine LAthe Gear cutting machine Broaching machine Broaching machine Drilling machine Special machine |

Crushed chips End milling |

☓ | 〇 | ☓ | 〇*2 | 〇 |

| Special helical shape 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Cylindrical shape 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Tangled chips 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Washing machine | Fine iron powder about 100μm |

〇 | △ | 〇*1 | - | ☓ |

| Hardening equipment | Fine iron particles of various shapes |

△ | △ | △*1 | ☓ | ☓ |

〇:Effectively functions and high collection rate.

△:Functions but collection rate and processing amount

expected to drop.

☓:Not suitable.

△:Functions but collection rate and processing amount

expected to drop.

☓:Not suitable.

*1:Normagnetic fine particles such as abrasives can be collected.

*2:Tow steps of chip collection and fine iron powder collection are possible.

*3:May not be collected by the standerd type. Please contact us.

*2:Tow steps of chip collection and fine iron powder collection are possible.

*3:May not be collected by the standerd type. Please contact us.