[Standard Type]

EPT-3060F |

[Application]

Most suitable for highly accurate grinding such as precision grinding and slicing.

[Features]

- Electricity is applied momentarily only to control the magnetomotive force when mounting and dismounting workpieces, minimizing heat generated internally to ensure high precision machining operations.

- Electricity needs not be applied continuously even when holding workpieces, helping reduce running costs.

- The holding power is maintained by the permanent magnet in the event of power failure, improving safety.

- An environment-friendly resin bonded face plate is employed.

- Type EPT-LW is equipped with a low magnetic force (weak attraction) control

function, which is difficult to achieve with conventional permanent electromagnetic

chucks, to facilitate stress relieving and workpiece positioning to the

same level achieved by electromagnetic chucks. (When the low magnetic force

control function is active, the chuck is in the continuous power-on state.)

Note that this must be used together with the dedicated Chuck Master (Type

EPH-LW)

|

[Low Magnetic Force Control Type]

EPT-LW1530F

|

|

[Standard Type]

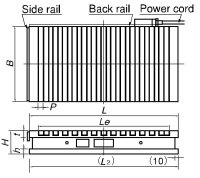

| mm(in) |

| Model |

Nominal

Dimensions |

Top Plate |

Pole Pitch |

Bottom Plate |

Height |

Voltage |

Current

|

Power

cord |

Mass |

Electro Chuck

Master |

| B |

L |

Le |

t |

P |

L2 |

h |

H |

| EPT-1530F |

150(5.90) X

300(11.8) |

150

(5.90) |

300

(11.8) |

240

(9.44) |

20.5(0.80) |

14(2+12)

0.55 (0.07+0.47) |

300

(11.8) |

20

(0.78) |

80

(3.14) |

90

VDC

|

1.91A |

2m

(78.7) |

24kg

/52.9lb |

EPS-215B

|

| EPT-1535F |

150(5.90) X

350(13.7) |

350

(13.7) |

296

(11.6) |

350

(13.7) |

2.43A |

28kg

/61.7lb |

| EPT-1545F |

150(5.90) X

450(17.7) |

450

(17.7) |

380

(14.9) |

450

(17.7) |

2.64A |

36kg

/79.3lb |

| EPT-2050F |

200(7.87) X

500(19.6) |

200

(7.87) |

500

(19.6) |

436

(17.1) |

500

(19.6) |

5.88A |

3m

(118.1) |

53kg

/116.8lb |

| EPT-2060F |

200(7.87) X

600(23.6) |

600

(23.6) |

548

(21.5) |

600

(23.6) |

7.87A |

65kg

/143.3lb |

| EPT-3060F |

300(11.8) X

600(23.6) |

300

(11.8) |

529

(20.8) |

25.0(0.98) |

19.5(2.5+17)

0.79 (0.09+0.66) |

25

(0.98) |

100

(3.93) |

6.14A |

140kg

/308.6lb |

| EPT-4080F |

400(15.7) X

800(31.4) |

400

(15.7) |

800

(31.4) |

724

(28.5) |

800

(31.4) |

11.0A |

5m

(196.8) |

211kg

/465.1lb |

| EPT-40100F |

400(15.7) X

1000(39.3) |

1000

(39.3) |

919

(36.1) |

1000

(39.3) |

12.5A |

265kg

/584.2lb |

| EPT-5080F |

500(19.6) X

800(31.4) |

500

(19.6) |

800

(31.4) |

724

(28.5) |

800

(31.4) |

9.01A |

| EPT-50100F |

500(19.6) X

1000(39.3) |

1000

(39.3) |

919

(36.1) |

1000

(39.3) |

11.7A |

330kg

/727.5lb |

*The chuck controller and clamp parts are not included.

*The KANETEC chucks work best when a KANETEC chuck controller is used.

*Turning the parmanent electromagnetic chucks on and off must be limited

to once per several minutes.

If on/off operations are repeated frequently, the chucks may be damaged by overheat. |

|

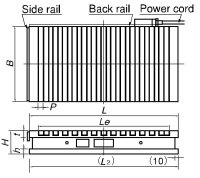

[Low Magnetic Force Control Type]

| mm(in) |

| Model |

Nominal

Dimensions |

Top Plate |

Pole Pitch |

Bottom Plate |

Height |

Voltage |

Current

|

Power

cord |

Mass |

Electro Chuck Master |

| B |

L |

Le |

t |

P |

L2 |

h |

H |

| EPT-LW1530F |

150(5.90) X

300(11.8) |

150

(5.90) |

300

(11.8) |

240

(9.44) |

20.5

(0.80) |

14(2+12)0.55

(0.07+0.47) |

300

(11.8) |

20

(0.78) |

80

(3.14) |

180

VDC

|

0.80A |

2m

(78.7) |

24kg

/52.9lb |

EPH-LW205B

EPH-LWE205B |

| EPT-LW1535F |

150(5.90) X

350(13.7) |

350

(13.7) |

296

(11.6) |

350

(13.7) |

0.93A |

28kg

/61.7lb |

| EPT-LW1545F |

150(5.90) X

450(17.7) |

450

(17.7) |

380

(14.9) |

450

(17.7) |

1.17A |

36kg

/79.3lb |

| EPT-LW2050F |

200(7.87) X

500(19.6) |

200

(7.87) |

500(19.6) |

436(17.1) |

500

(19.6) |

3.31A |

3m

(118.1) |

53kg

/116.8lb |

| EPT-LW2060F |

200(7.87) X

600(23.6) |

600

(23.6) |

548

(21.5) |

600

(23.6) |

3.82A |

65kg

/143.3lb |

| EPT-LW3060F |

300(11.8) X

600(23.6) |

300

(11.8) |

529

(20.8) |

25.0

(0.98) |

19.5(2.5+17)0.79

(0.09+0.66) |

100

(3.93) |

2.55A |

140kg

/308.6lb |

| EPT-LW4080F |

400(15.7) X

800(31.4) |

400

(15.7) |

800

(31.4) |

724

(28.5) |

800

(31.4) |

6.59A |

5m

(196.8) |

211kg

/465.1lb |

EPH-LWE210B |

| EPT-LW40100F |

400(15.7) X

1000(39.3) |

1000

(39.3) |

919

(36.1) |

1000

(39.3) |

6.45A |

265kg

/584.2lb |

| EPT-LW5080F |

500(19.6) X

800(31.4) |

500

(19.6) |

800

(31.4) |

724

(28.5) |

800

(31.4) |

5.41A |

EPT-

LW50100F |

500(19.6) X

1000(39.3) |

1000

(39.3) |

919

(36.1) |

1000

(39.3) |

6.00A |

330kg

/727.5lb |

*The chuck controller and clamp parts are not included.

*The KANETEC chucks work best when a KANETEC chuck controller is used.

*Turning the parmanent electromagnetic chucks on and off must be limited

to once per several minutes.

If on/off operations are repeated frequently, the chucks may be damaged by overheat. |

|