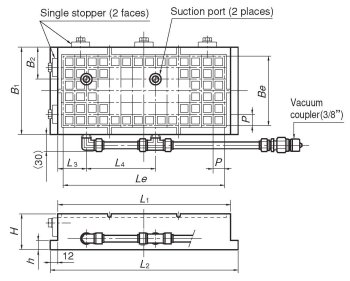

| VACUUM CHUCK (GRID SEAL TYPE) [Model KVR-G] | CATALOG |

KVR-G1530

KVR-G100140 An example of special specification  KVR-GR An example of special specification |

[Application] Suitable for grinding by vacuum chucking such nonmagnetic workpieces as aluminum alloy, copper alloy, stainless steel and plastics. [Features]

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| VACUUM SYSTEM [VPU-EG] | CATALOG |

| Light weight and compact. Satisfactory functions ! |

VPU-EG

| [Application] A vacuum system dedicated to the grid seal type vacuum chucks. [Features]

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||