| VACUUM CHUCKS [Model KVR] | CATALOG |

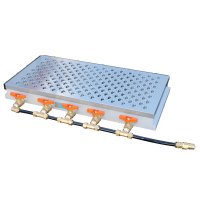

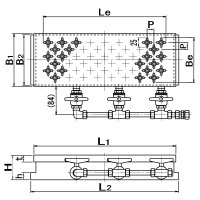

KVR-2D3060

|

[Application] Chucks to hold workpieces by utilizing atmospheric vacuum pressure. Nonmetallic and nonmagnetic materials can be held and machined. These chucks are suitable for grinding and cutting plastics and grinding aluminum, brass, stainless steel, ceramic and glass. [Features]

<Precautions for use>

The vacuum chuck is of such construction that the inside of the chuck is exhausted by a vacuum pump to reduce the internal pressure and a workpiece is held by atmospheric pressure. Therefore, the holding power is determined by a difference from atmospheric pressure and holding area. Due to physical restrictions, a difference in pressure that can be obtained by a pump is about 80 kPa (600 mmHg) in consideration of the upper limit of available exhaust efficiency. Since the same holding power as about 80 kPa (0.8 kgf/cm2) can be obtained, if the holding area of a workpiece is 100 cm2, it is held by a holding power of about 800 N (80 kgf). Note, however, if the holding face of workpieces is rough or distorted, if small, atmospheric pressure leak occurs to decrease the holding power significantly. For such workpieces, some leak preventing measures must be taken. Workpieces could be deformed by heat generated during machining depending on materials and thickness of workpieces. Pay attention to machining methods. In particular, thin stainless steel plates deform due to machining heat largely and are difficult to hold. If you have questions, please contact us. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| VACUUM SYSTEM [Model VPU] | CATALOG |

VPU-E10  VPU-D20 |

[Application] A pressure reducing device dedicated to vacuum chucks. The chuck side is exhausted continuously to effectively maintain atmospheric pressure acting on workpieces on the chuck work face. Note, however, this equipment must not be modified to use it as a pressure vessel. [Features]

A vacuum system to reduce pressure by jetting air at high pressure (principle of the spray gun). This is recommended where an air line by use of a compressor is installed. This type can be used for both wet and dry machining operations. However, the use of a lubricator in the air line must be avoided. A vacuum system to reduce pressure by exhausting by a pump driven by a motor. A power source only is required to obtain an independent vacuum source. Note, however, this is recommended only for dry machining operations. If the physical contact with the bottom face of work-pieces is poor, a large amount of air leaks, requiring a large exhaust amount. In such a case, a blower type is required for dry operations and a water-sealed vacuum pump is required for wet operations depending on work conditions. Please contact us. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

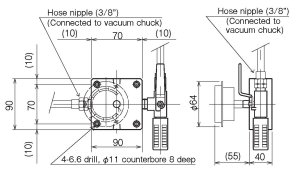

| OPERATION BLOCK WITH VACUUM GAGE [Model VPU-OV] | CATALOG |

VPU-OV |

[Application] An option to facilitate the use of vacuum chucks. [Features]

|

|